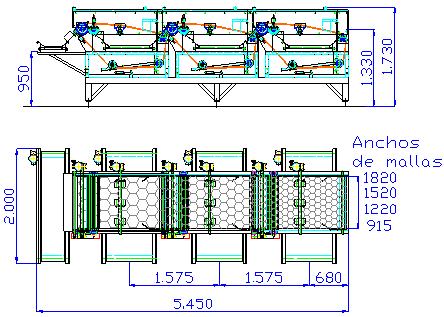

The screen grader is a very compact machine with a production of 8 to 30 tonnes per hour depending on the width of the machine. The treatment of the product is very gentle.

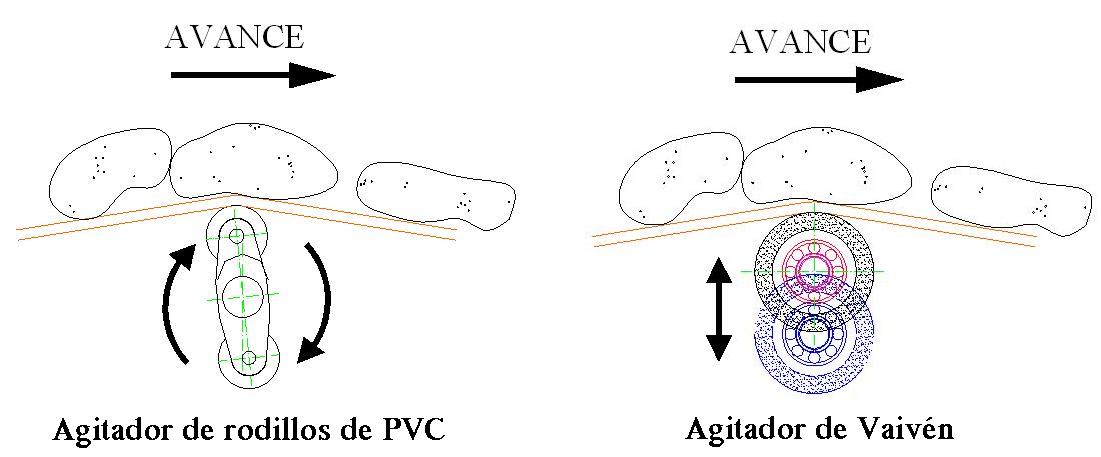

The change of grading screen is done quickly and easily. There are several types of agitator rollers. The “vaivén” model (or swing model), and the model of PVC rollers.

The grading screens can be square, round or hexagonal according to the customer´s needs. They can be made of metal, rubber or PVC.

Operation of the grading equipment

Video and instructions for use

The product enters the grader, and advances by resting on a grading screen of a particular size, at the same time that it is positioned in the gaps of the grading mesh. With the movement of a stirring roller, the product having a size smaller than that of the grading screen falls on a conveyor belt located below it. The larger product continues to advance to the next grading screen, which will have another caliber or size.

The machine has an extracting roller at the end of each grading screen to remove the product that was embedded in the screen without having fallen through the gap, and so on, along each of the mesh sizes that you want to install in the grader. At the end of the machine is placed another belt that is responsible for collecting the larger product that did not match any of the graders.

There are several types of agitator roller, the swing model and the PVC roller model.

The grading screens are easily interchangeable. If at any time you want to change the size of the graders, this maneuver can be made very quickly; you just have to untangle the grading screen using the lever of the tensioning roller and release the mesh of the hook joints with which it is built.

Photo Gallery