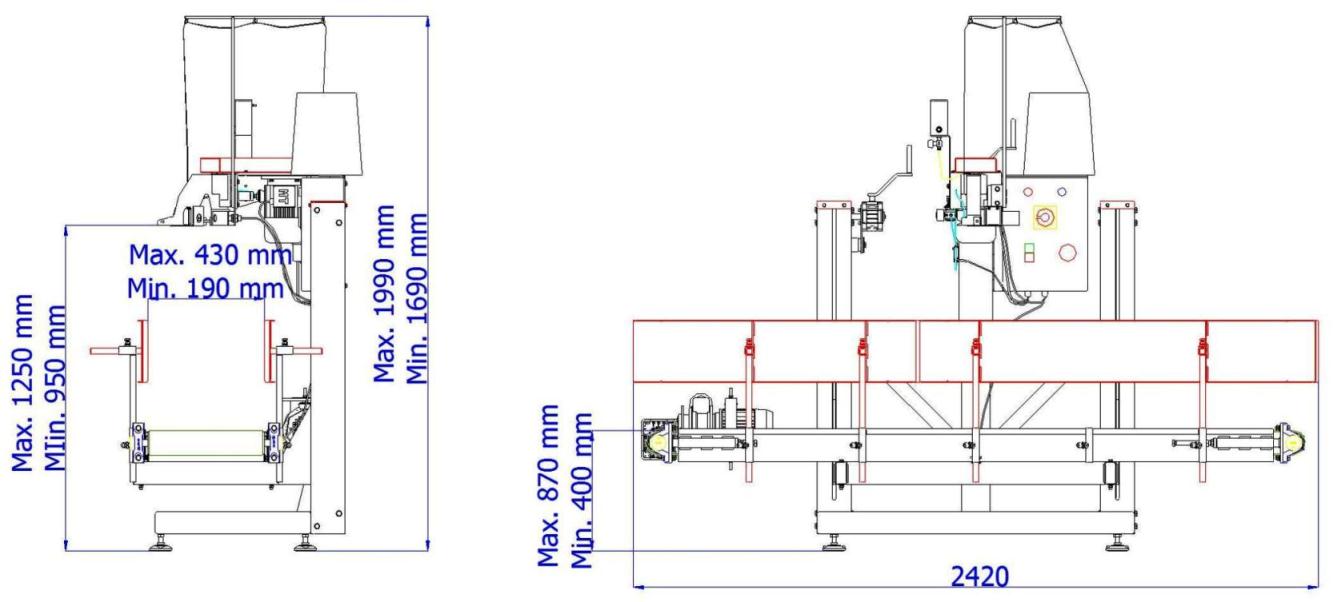

The sewing column machine is a very robust machine whose dimensions are adjusted to the needs of the customer. The production of sewing is 600 bags per hour.

It is possible to regulate, easily and comfortably, the height of the tape for the different types of bags. The sides of the belts are interchangeable to fit the configuration most appropriate for the customer.

The machine does not require any kind of special maintenance.

Operation of the sewing column

Video and instructions for use

Continuous procedure

In continuous mode, the belt is always running. The operator positions the product bag on the conveyor belt, which will advance to the sewing machine. When you pass in front of the detector, the sewing machine will start until the detector stops seeing the bag. After a few seconds, the sewing machine stops, and cuts the thread. The sewn bag goes to the end of the belt where another operator picks it up

Batch procedure

In batch mode, the belt is stopped. The operator places the product bag on the conveyor belt and activates the pedal. At that moment, the belt starts and the bag advances to the sewing machine. When the bag passes in front of the detector, the sewing machine starts sewing until the detector stops seeing the bag. After a few seconds, the stitch stops, and cuts the thread. The bag advances for a few seconds and stops.

Photo Gallery