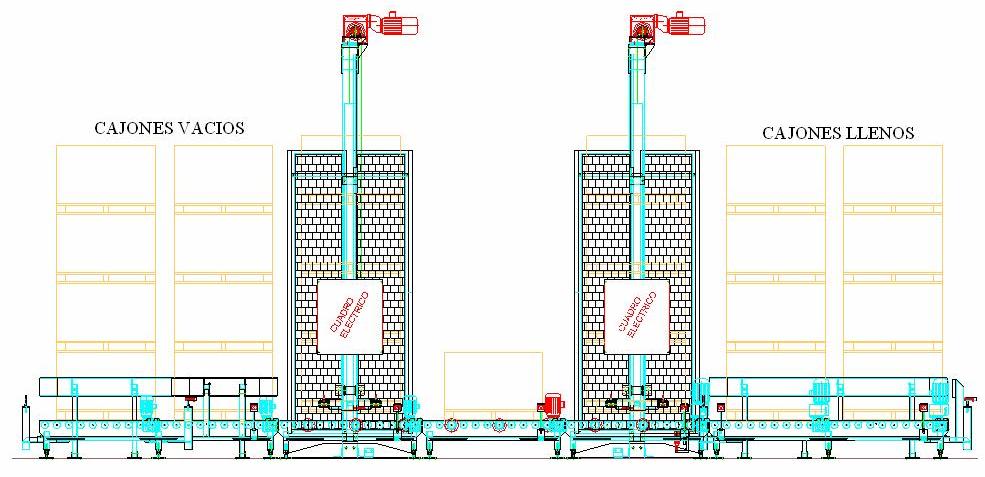

Palletizer / Depalletizer for boxes, very robust machine for palletizing or depalletizing automatically towers of up to 4 boxes with a capacity of palletizing and depalletized of 120 boxes / hour.

To work with the machine only requires an operator, who is responsible for operating the machine lever to change the filled box for another empty box and accommodate the product by making a last selection.

When the forklift enters the side of the machine to collect a completed tower, sensors prevent the corresponding conveyor from being started, while the rest of the machine follows its process. The same thing happens in the boxes feed area.

The Palletizer-Depalletizer of boxes Procedure

Video and instructions for use

The operator feeds with towers of 2, 3 or 4 empty boxes to the entrance conveyor. Once the forklift has left the area of the machine, the tower advances to the depalletizer column where the process begins. The conveyor is feeding empty boxes that the column is depalletizing, as either the operator or a machine that is placed in the central conveyor requires for the filling of the boxes.

The filled boxes advance to the second column for the palletizing of towers of 2, 3 or 4 boxes (which was selected at the beginning of the job). Once a tower is palletized completely, it is advanced to the next conveyor where it will wait for the operator of the forklift to be removed it for storage.

The final conveyor can hold several boxes towers to prevent the machine from stopping when a tower is waiting to be removed.

Photo Gallery