There are two models of potato washing machine:

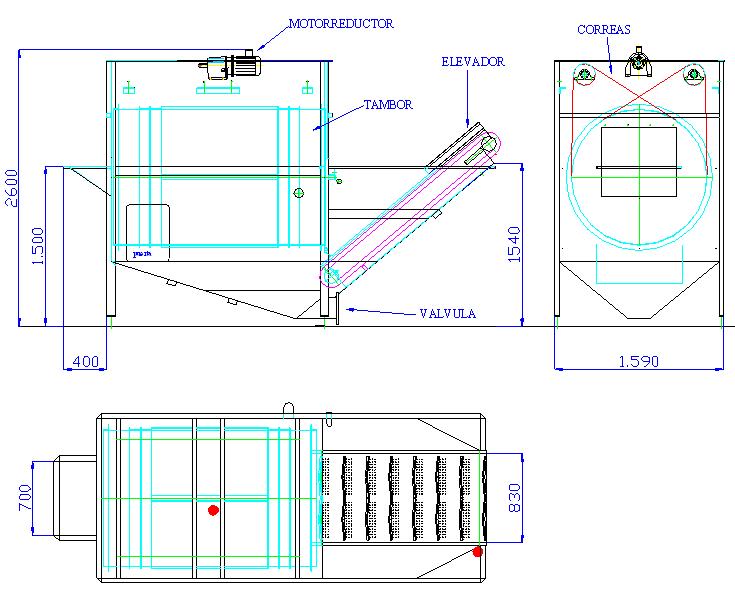

- Submerged drum washer model for the production between 5 to 30 Tn/h. The drain valves are placed according to customer needs, either at the bottom or laterally. It is supplied with an elevator for the exit of product with showers for the final rinse.

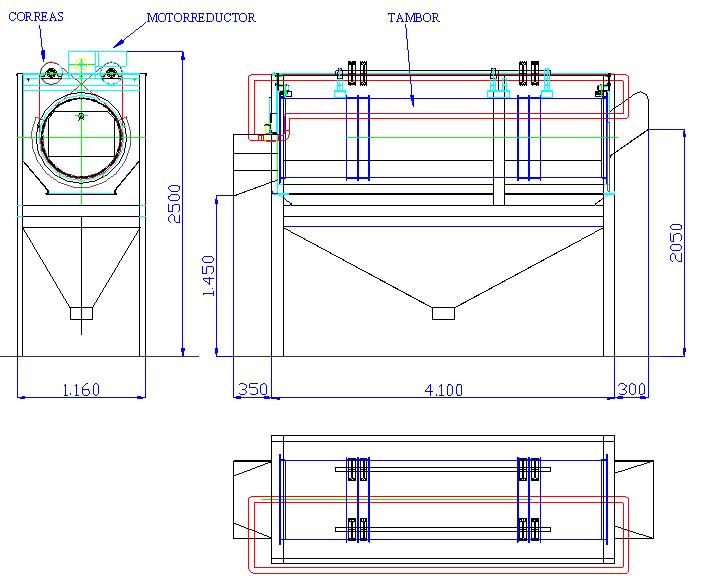

- Showers with rotating drum model. This model of washing machine of potatoes allows a very fast washing. The change of product is performed quicker than in the submerged drum models. The potatoes are rubbed between them increasing the level of cleaning of the product.

Process of the potato washing machine

Video and instructions for use

The product to be washed enters the machine through the inlet (or enter gate) into the drum, which is partially submerged and rotating in one direction by a transmission of belts connected to a motor-reducer. The product stays on the drum and is constantly stirred by rubbers in the form of a spiral to be dragged; this causes the potatoes to be cleaned when submerged in the water.

At the end of the process, the operator opens the hatches that hold the product inside the drum, and leaves it to an elevator with rinsing showers that picks them up and deposits it on the next machine.

The machine has valves for draining the water and a level system so that there is always the same amount of water in the machine.

In the new shower model with rotating drum, the potatoes are cleaned by a constant stream of water along the path of the drum. The cleaning of the product is done by rubbing the product between them and at the end of the path, it leaves by a fall to the next machine.

Photo gallery