Operation of Vibrating Onion Toppers

Video and instructions for use

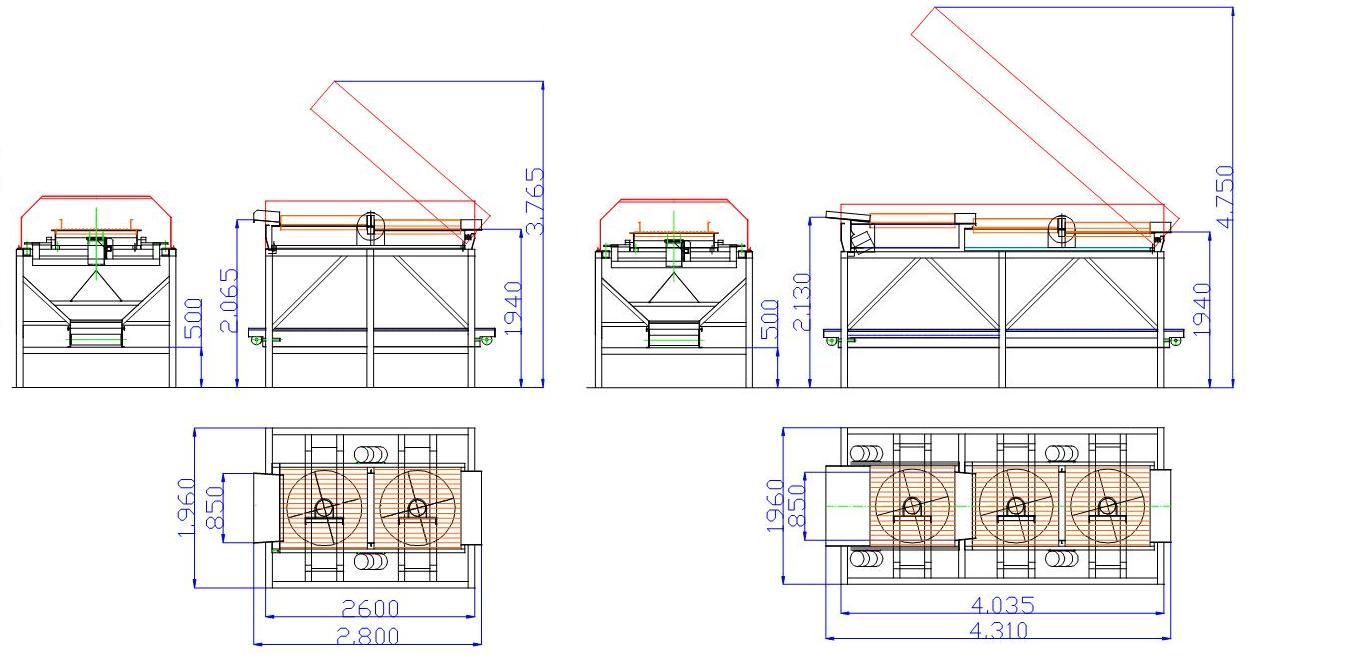

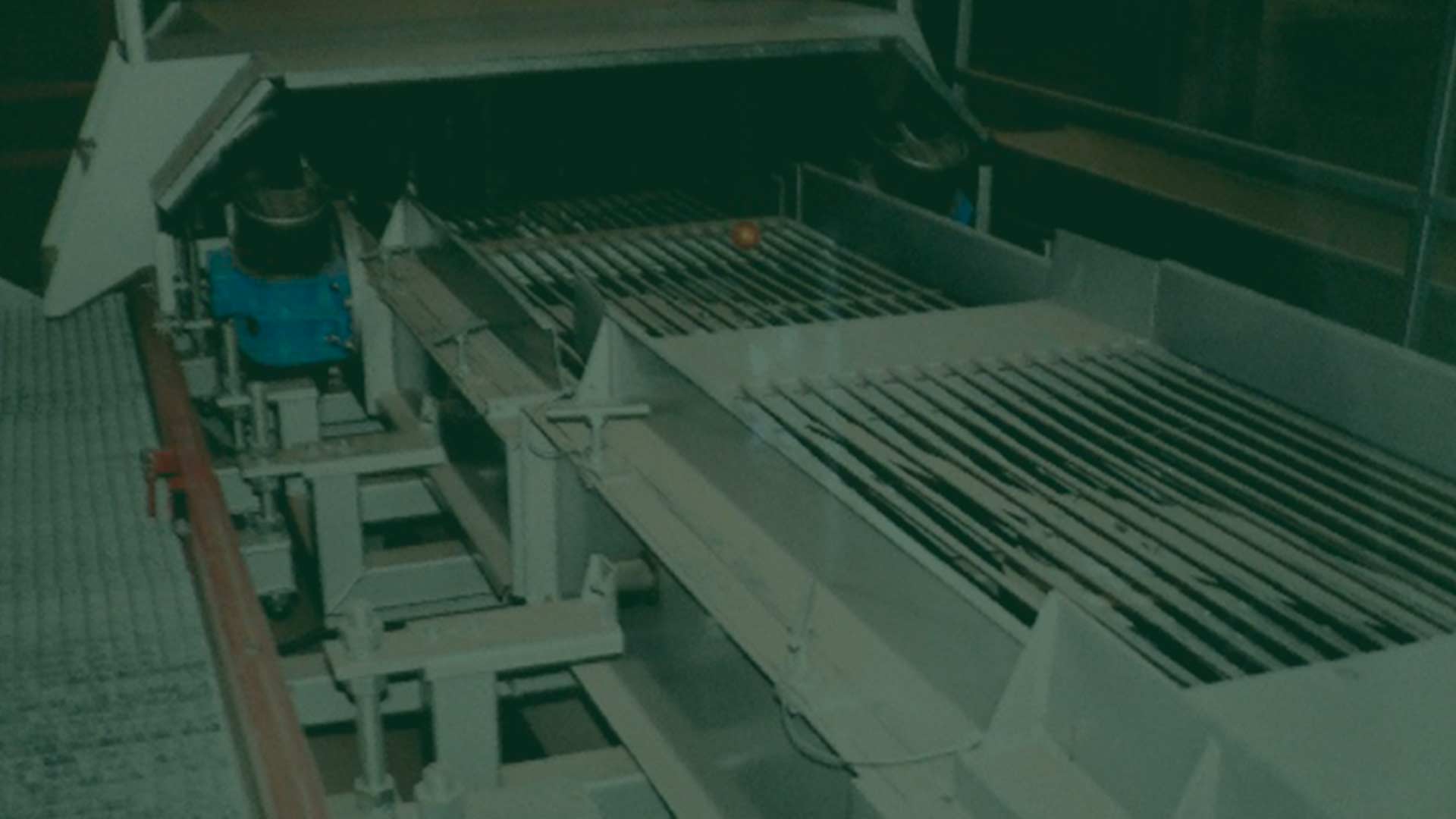

The onions enter through the inlet gate passing through three trays of rods. These have a spacing between rods of 33 mm, although this separation can vary according to the needs of the customer, manufacturing trays with different separations.

The product advances through a gentle vibration that, at the same time, causes it to be placed on itself so that it is positioned between the rods. Lower blades, which rotate at high speed, are responsible for cutting the onion stem, dropping it on a conveyor belt collecting waste. The trays, like the blades, can be easily disassembled.

After passing through the three cutting trays, the product exits through the outlet, to discharge onto the next machine.

The topper has an electronic system to regulate the feed and an electronic system to adjust the cutting speed of the blades. It also has a top safety cap. When this lid is removed to clean the machine, the whole set is stopped quickly and automatically.

Although the machine requires little maintenance, thanks to its robustness, it needs a daily cleaning due to the nature of its work.

Photo gallery